Understanding the Role of Motor Position Sensors in Modern Machinery

Motor position sensors are critical components in various industrial applications, providing precise data on the position of motors. Whether in manufacturing, robotics, or automotive industries, these sensors ensure optimal performance and efficiency by delivering accurate feedback on motor positions. For business owners looking to enhance their machinery's reliability, understanding the importance and functionality of motor position sensors is essential.

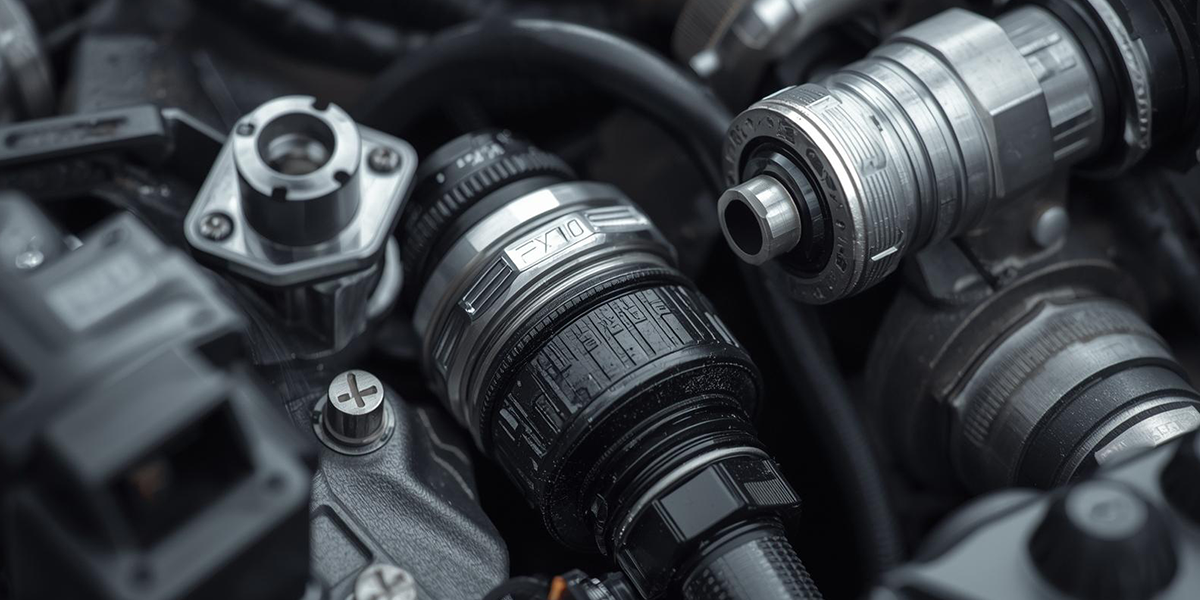

What Are Motor Position Sensors?

Motor position sensors are devices that detect and report the position of a motor shaft. They are used in a variety of applications to provide feedback for motor control, ensuring that the machinery operates within its intended parameters. These sensors are pivotal in maintaining efficiency, safety, and performance in automated systems.

Q: Why are motor position sensors crucial in industrial applications?

A: Motor position sensors are vital for precision control in machinery, helping to maintain optimal performance, safety, and efficiency by providing accurate feedback on motor positions.

Types of Motor Position Sensors

There are several types of motor position sensors, each suited to different applications and environments:

- Rotary Encoders: These sensors convert the angular position or motion of a shaft to digital or analog output signals. They are commonly used in robotics and CNC machinery.

- Linear Position Sensors: Ideal for applications requiring linear movement measurement, these sensors are used in hydraulic or pneumatic systems.

- Potentiometers: These are simple and cost-effective sensors that provide a variable resistance based on the shaft's position.

- Hall Effect Sensors: These are used in environments where contactless measurement is essential, offering high reliability and durability.

Benefits of Using Motor Position Sensors

The integration of motor position sensors into your systems offers numerous benefits:

- Increased Efficiency: By providing precise feedback, sensors enable better control and adjustment of machinery, leading to enhanced efficiency.

- Improved Safety: Sensors help prevent machinery from operating outside of safe parameters, reducing the risk of accidents.

- Cost Savings: Accurate position monitoring reduces wear and tear on equipment, minimizing maintenance costs and prolonging equipment life.

Choosing the Right Motor Position Sensor for Your Needs

Selecting the appropriate motor position sensor requires understanding your specific application needs. Consider the following factors when choosing a sensor:

- Environment: Ensure the sensor can withstand your operating environment's conditions, such as temperature, humidity, and exposure to chemicals.

- Accuracy Requirements: Determine the level of precision needed for your application and choose a sensor that meets those requirements.

- Integration Capability: Consider how easily the sensor can be integrated into your existing systems and its compatibility with other components.

UniMeasure Inc: Your Partner in Precision Sensor Solutions

At UniMeasure Inc, we understand the importance of reliable motor position sensors for your business. Our range of sensors is designed to meet the diverse needs of various industrial applications, ensuring precision, durability, and efficiency. With our expertise and commitment to quality, we can help you find the perfect sensor solution tailored to your specific requirements.

For more information on motor position sensor for sale and how we can support your business, contact UniMeasure Inc today. Let us be your trusted partner in achieving precision and excellence in your operations.